Ready Mix Concrete

Ready Mix Concrete

Helping you construct your world

Grade M5 to M70

AVSTech Group ensures Best Quality Ready Mix Concrete – AVSTech Group commenced operations in 1995 with the Intention to Providing Best Quality RMC.

Ready Mix Concrete and Customer Satisfaction along with On-Time Delivery Services has made us Recognized in the construction business verticals. You will be Served by our Highly Qualified Team Members who will Ensure that you get Top-Quality Ready-Mix Concrete-RMC concrete that will make your development keep going for ages.

AVSTech – Ready Mixed Concrete (RMC) is delivered in its totally automated BVQI certified batching plants @ 60m3/hr. AVSTech claims and operates 5 business plants and 4 dedicated Plants Capable of providing 2000m3 each day The Storage capacity of 800 tons of Cement and GGBS in each plant. A fleet of 75 Transit blenders, 15 Line pumps, and 4 Boom Pumps. AVSTech Concrete’s accomplished logistics group works intimately with you to guarantee that the concrete of imperative quality is delivered on time and in the appropriate quantities.

AVSTech Concrete has the experience and the ability to design, produce and deliver a wide scope of ready mixed concrete variations to meet explicit requirements. Completely equipped laboratories at all plants to do different tests on concrete and on constituent raw materials. Concrete blends of different grades are planned in the lab according to set up systems to follow BIS specifications.

The Quality assurance systems and techniques carried out by AVSTech monitor each phase of the entire business process. The quality system is intermittently inspected for development on a persistent basis. Compressive strength of cement: Cubes are cast at the plant as well as at the site. The client can therefore ascertain that the concrete he receives at his site guarantees better strength of the structures. The slump is tested immediately after production and at the time of pour. The required slump is guaranteed. Test Certificates are given routinely for the testing of concrete.

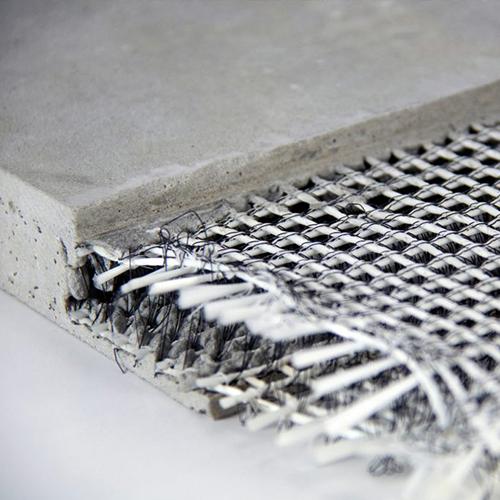

Fibre Reinforced Concrete

Fibre Reinforced Concrete is a unique product with inherently enhanced resistance against tensile stresses which leads to shrinkage cracks at initial and later stages of hardening of concrete. This is achieved by introduction of polypropylene and polyester fibers. These fibers compensate the lack of tensile strength of the concrete by taking the tensile stress themselves and prevent cracks. Special features given below:

- Very high resistance to shrinkage cracks

- Robust homogeneous mix

Applications

- In regular slabs, slabs with lean sections and rooftops

- In concrete having high cement content which is more prone to shrink.

- Screeds, parking lot, CC roads and walkways

Self Compact Concrete

Self Compact Concrete is a special concrete having self flowing, self leveling and self consolidating properties developed to make construction process easy, fast and efficient. AVS Tech Self Compact Concrete is developed using new generation admixtures technology allowing it to be self flowing properties while maintaining low viscosities and yield stress of the mix without any segregation or bleeding.

It is one of the solutions towards noise-free placement of concrete with challenging task of placing concrete in to heavily reinforced structure sections & for night concreting in residential area to reduce eliminate noise of vibrators.

Applications

- Deep columns and shear walls

- Suitable for aluminum form shuttering

- Beams and Slabs

- Densely reinforced and lean sections

- Raft and deep foundations

- Complicated and intricate structures

High Performance Concrete

High Performance Concrete is a high grade high performance concrete capable of achieving 100Mpa compressive strength. AVS Tech High Performance Concrete is solution that caters to industry’s need for high performance concrete. It is produced by multiple blend of binder materials along with the use new generation superplasticizers. AVS Tech High Performance Concrete is a blessing for modern urban high rise structures.

Applications

- High rise buildings and lean columns

- Core walls and shear walls

- Columns for bridges, elevated roads

- Long span girders, Deck slab and piers

Coloured Concrete

AVS Tech Coloured Concrete is a decorative concrete solution available in various colors, textures and patterns. It is available in two forms- one of plain colored concrete and another one is stamped concrete. Both these solutions are applicable for vertical and horizontal use. UV stable high quality color pigments are used to ensure color fastness for longer period.

Applications

- Ideal for lobbies of residential buildings and malls

- Decorative floorings and walls

- Ideal for landscaping

- Decorative precast panel

- Walk ways

Temperature Controlled Concrete

AVS Tech Temperature Controlled Concrete is a solution to keep temperature of the concrete and structure within desirable limits to minimize the ill effects like thermal cracking, early drying or setting of concrete due to high heat of hydration in mass concreting pours. Thermally controlled Ingredients and their proportions are carefully selected to minimize the heat of hydration and lowest possible concrete temperature while placing. The special feature is Reduces core temperature and differential temperature in mass pours.

Applications

- Mass Concreting

- Raft Foundations

- Shear walls & core walls

- Concrete with high cement content

- Columns with large sections

Lightweight Concrete

AVS Tech Lightweight Concrete is new generation light weight concrete produced by introducing foam in the concrete Foam is generated separately by use of synthetic based air entrainer and foam generator. Synthetic air entrainer entrains bubbles in the concrete thus reducing the density of the concrete and making it much lighter in weight as compared to conventional concrete.

Applications

- Lightweight topping over roof slab

- Thermal Insulation layer on roof top

- Filling of trenches in roadways

- Sound insulation layer over intermediate slabs

- Screed concrete layer over raceways in commercial buildings

- Filling of sunken slab of toilets after pipelines are laid

- Filling of cable trenches, which may be required to be removed in future for repairs

Grade M5 to M70

AVS Tech Toughcrete addresses the key requirement of high durability and service life of concrete structures. Binder materials are carefully selected after numerous studies and testing to increase the durability and service life of concrete structures. AVS Tech Toughcrete withstands the test of time against various harsh environmental conditions & exposures.

Applications

- Concrete directly in contact with soil with high concentration of sulphates and chlorides

- Concrete susceptible to chemical attack like sewage plants, pumping stations and chemical factories

- Marine structures, loading dock and underwater construction

- Underground tunnels and segments

- Structures exposed to severe, very severe and extreme exposure conditions