Aggregates

Aggregates

M-Sand

- Well-graded and conforms to IS 383-2016

- With a robust set up of 5 Quarries and 5 Crushing Plants, AVSTech is progressing rapidly by providing the quality products.

- The boulders are crushed with three stage configuration consisting of a Jaw crusher followed by a Cone Crusher and finally a Vertical Shaft lmpactor(VSI).

- Backed by Metso and Pozolona plant and machinery with a fleet of 125 tippers, AVSTech has a strong production and logistics base.

- AVS MSand is free from elongated and flaky particle since it is shaped cubically using VSI shaping machine. The cubically shaped particles give high strength and long life to concrete

- AVSTech Concrete’s experienced logistics team works closely with you to ensure that the concrete of requisite quality is delivered on time and in the appropriate quantities.

Greater Durability

M-Sand has balanced physical and chemical properties that can withstand any aggressive environmental and

climatic conditions as it has enhanced durability, greater strength and overall economy. Usage of M-Sand can

overcome the defects occurring in concrete such as honey combing, segregation, voids, capillary etc.

High Strength

The superior shape, proper gradation of fines, smooth surface texture and consistency in production parameter of chemically stable sands provides greater durability and higher strength to concrete by overcoming deficiencies like segregation, bleeding, honey combing, voids and capillary.

Greater Workability

The crusher dust is flaky and angular in shape which is troublesome in working. There is no plasticity in the mortar which makes it even difficult for the mason to work, whereas the cubical shape with grounded edge and superior gradation gives good plasticity to mortar providing excellent workability.

Offsets Construction Defects

M-Sand has optimum initial and final setting time as well as excellent fineness which will help to overcome the deficiencies of concrete such as segregation, bleeding, honeycombing, voids and capillary.

Economy

Usage of M-Sand can drastically reduce the cost since like river sand. In International Construction Scenario sand is manufactured & used, which gives superior strength & its cubical shape ensures significant reduction in the cement used in the concrete

Eco-Friendly

M-Sand is the only alternative to river sand. Dredging of river beds to get river sand will lead to environmental disaster like ground water depletion, water scarcity, threat to the safety of bridges, dams

Plastering Sand

- AVSTech Plaster sand is a premium product manufactured using 5 stage processing

- AVSTech Plaster sand allows you to achieve a mix ratio of 1:6 (cement:sand), which means that you can replace expensive cement with affordable sand, effectively bringing down overall cost of construction.

- AVSTech Plaster sand offers minimum bounce back during plastering, thereby enhancing productivity and reducing wastage.

- AVSTech Plaster sand offers more workability, which enables masons to work faster and complete jobs quicker. Plus, it contains no deleterious material and hence eliminates the need for sieving at site resulting in substantial savings of precious time and money and cost

- AVSTech PSand lends the plaster greater strength for long-lasting, durable constructions. It helps achieve plaster thickness in a single coat and is ideal for applying multiple coats.

- Manufactured in a controlled, fully automated plant, you are assured of consistent quality so that the integrity of the construction is not compromised.

WMM (Wetmix Macadam)

GSB (Granular Sub-base)

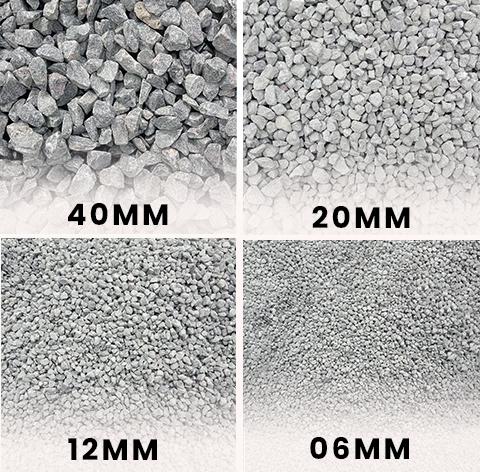

6MM, 12MM, 20MM and 40MM Jelly (VSI)

- Well graded and conforms to IS 383-2016

- With a robust set up of 5 Quarries and 5 Crushing Plants, AVSTech is progressing rapidly by providing the quality products.

- The boulders are crushed with three stage configuration consisting of a Jaw crusher followed by a Cone Crusher and finally a Vertical Shaft lmpactor (VSI).

- Backed by Metso and Pozolona plant and machinery with a fleet of 125 tippers, AVSTech has a strong production and logistics base.

- AVSTech Aggregates are free from elongated and flaky particle since it is shaped cubically using VSI shaping machine. The cubically shaped particles give high strength and long life to concrete

- Well graded and conforms to IS 383-2016

- With a robust set up of 5 Quarries and 5 Crushing Plants, AVSTech is progressing rapidly by providing the quality products.

- The boulders are crushed with three stage configuration consisting of a Jaw crusher followed by a Cone Crusher and finally a Vertical Shaft lmpactor (VSI).

- Backed by Metso and Pozolona plant and machinery with a fleet of 125 tippers, AVSTech has a strong production and logistics base.

- AVSTech Aggregates are free from elongated and flaky particle since it is shaped cubically using VSI shaping machine. The cubically shaped particles give high strength and long life to concrete

- Well graded and conforms to IS 383-2016

- With a robust set up of 5 Quarries and 5 Crushing Plants, AVSTech is progressing rapidly by providing the quality products.

- The boulders are crushed with three stage configuration consisting of a Jaw crusher followed by a Cone Crusher and finally a Vertical Shaft lmpactor (VSI).

- Backed by Metso and Pozolona plant and machinery with a fleet of 125 tippers, AVSTech has a strong production and logistics base.

- AVSTech Aggregates are free from elongated and flaky particle since it is shaped cubically using VSI shaping machine. The cubically shaped particles give high strength and long life to concrete

- Well graded and conforms to IS 383-2016

- With a robust set up of 5 Quarries and 5 Crushing Plants, AVSTech is progressing rapidly by providing the quality products.

- The boulders are crushed with three stage configuration consisting of a Jaw crusher followed by a Cone Crusher and finally a Vertical Shaft lmpactor (VSI).

- Backed by Metso and Pozolona plant and machinery with a fleet of 125 tippers, AVSTech has a strong production and logistics base.

- AVSTech Aggregates are free from elongated and flaky particle since it is shaped cubically using VSI shaping machine. The cubically shaped particles give high strength and long life to concrete